Digital Twins for

Manufacturing

and Process Engineering

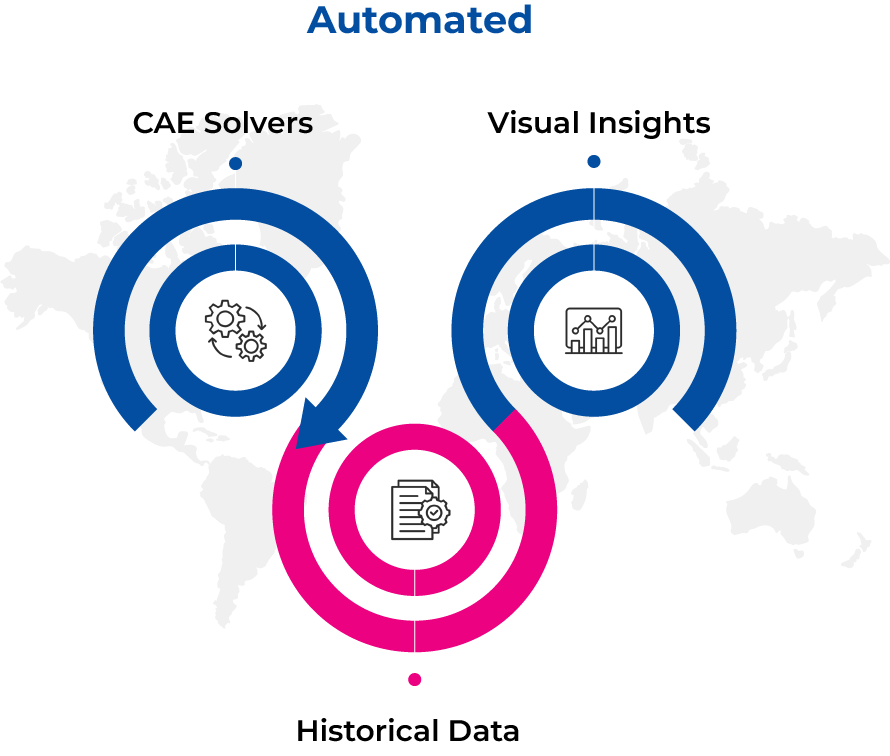

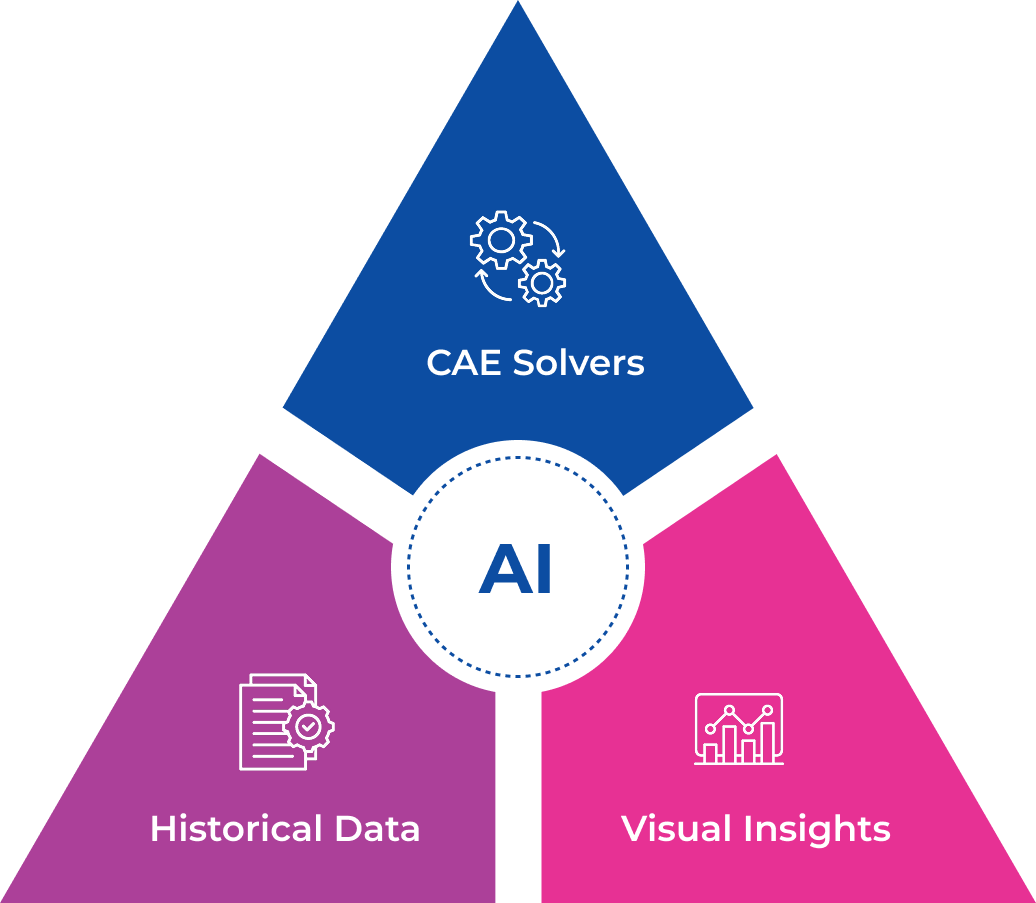

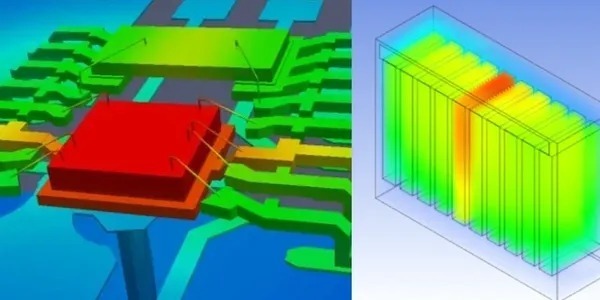

A complete digital twin is not built from sensor data

alone. While measured data is essential, real process understanding also depends on the physics

that governs the system and the actual behavior observed during operation. Intelimek builds

digital twins that integrate governing physics, comprehensive process data, and visual

understanding into a single, explainable framework that engineers can trust.

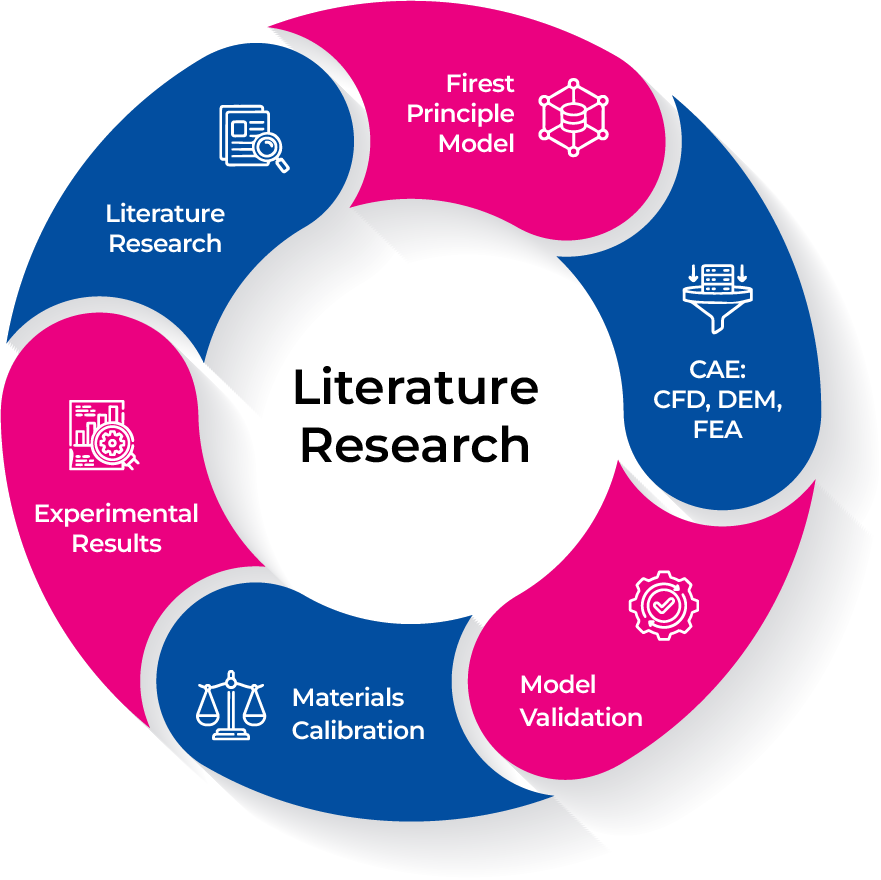

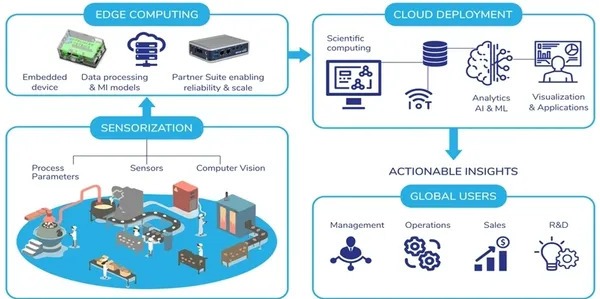

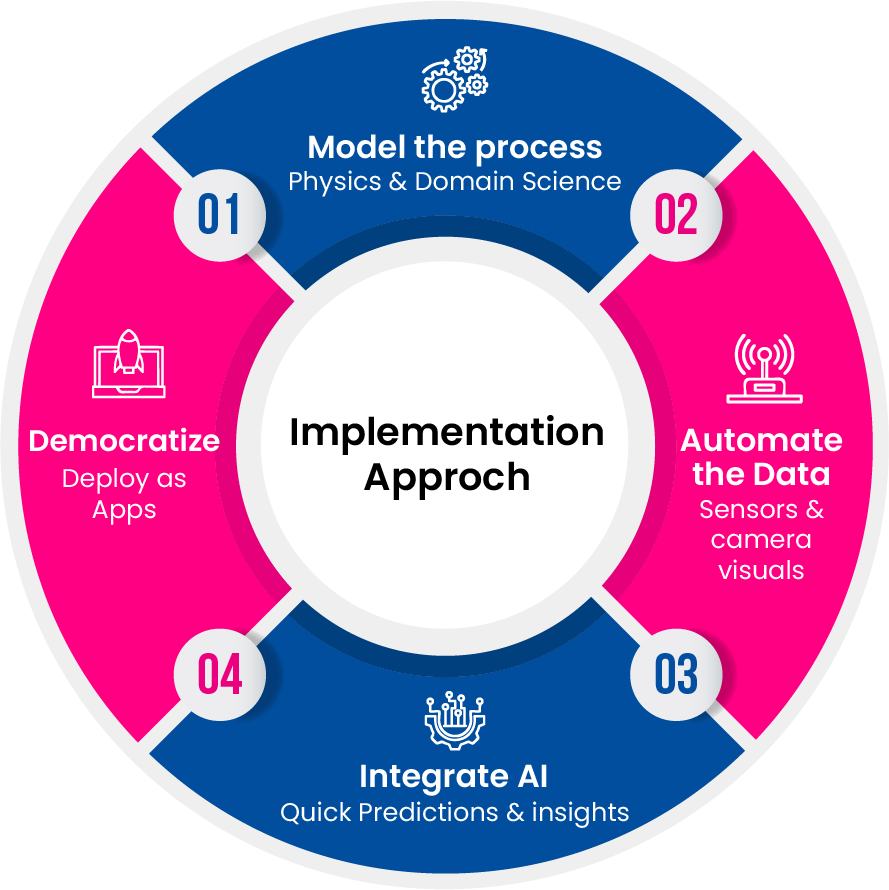

Our approach follows a structured four-step workflow that turns complex process behavior into

practical decision support across development, scale-up, and manufacturing.

Literature research and first-principles understanding of the process

Literature research and first-principles understanding of the process